Introduction

Water is one of the most important things in life. Every person, farm, and factory needs clean water. But many places in Uganda struggle to get enough clean water. Rivers and lakes may dry up during droughts. Some water is salty or dirty. This makes daily life hard for people and businesses.

One possible solution is industrial seawater RO desalination systems. These systems can turn salty water into fresh water that people and factories can use. In this blog, we will explain what these systems are, how they work, why they are important for Uganda, the challenges, and what the future might look like.

Note :- Industrial Seawater RO Desalination Systems in Uganda provide a reliable way to convert seawater into clean and usable water for industries. These systems are designed to support factories, power plants, and large facilities by ensuring a steady supply of safe water, even in areas facing water shortages. They help reduce dependence on freshwater sources and improve long-term water security.

What Is Seawater and Why Is It Salty?

Seawater comes from the ocean. It has a lot of salt and minerals. Human beings and many plants cannot drink salty water. Fresh water, like rainwater, rivers, or lakes, does not have too much salt. But in many places in Uganda, fresh water is not always enough.

Even though Uganda is a landlocked country (it does not touch the sea), it is possible to bring seawater technology into the country. This can be done by using plants near coastal areas or using salty underground water for treatment. The technology we are talking about is called Reverse Osmosis (RO).

What Is RO Desalination?

RO stands for Reverse Osmosis. This is a type of technology that removes salt and minerals from water.

In the process:

-

Water is pushed under high pressure through a special membrane (a very thin filter).

-

The membrane only lets water molecules pass, but it stops salt and most impurities.

-

The result is clean, fresh water that can be used for drinking, farming, and industry.

RO systems are used in many parts of the world to make seawater fresh and safe to use.

What Is an Industrial Seawater RO Desalination System?

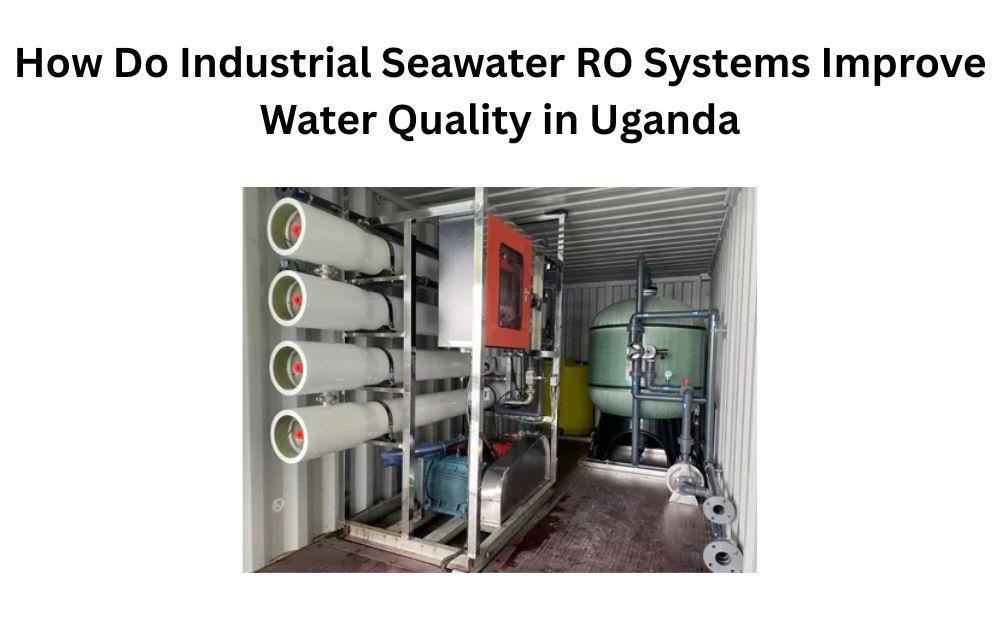

An industrial seawater RO desalination system is a large machine or group of machines that can take in salty water and produce a lot of fresh water every day.

Industrial systems are not small like home water filters. They are built on a large scale to support many people or a factory. Some key points are:

-

They can produce tens, hundreds, or even thousands of cubic meters of water per day.

-

They use high-pressure pumps to push water through the RO membranes.

-

They need energy to run the pumps and the system.

-

They have parts for pre-treatment, filtration, pumping, and cleaning.

These systems are very helpful when there is not enough good water available naturally.

Why Could Uganda Need This Technology?

Uganda faces many water challenges. Even though the country has many lakes and rivers, not all areas have enough fresh, clean water:

1. Water Scarcity During Dry Seasons

During long dry seasons, surface water levels drop. Rivers and lakes may shrink. People must dig deeper wells, but these sometimes bring salty water.

2. Salt in Groundwater

In some areas, the underground water is salty or brackish (slightly salty). This water is not good for drinking or farming. RO can help clean this water and make it usable.

3. Growing Population

The population of Uganda has been growing fast. This increases the demand for fresh water for homes, farms, and factories.

4. Need for Industrial Water

Many industries need clean water for their machines and products. For example, food processing, beverage companies, and textiles all need very good water quality.

Because of these reasons, industrial desalination systems may help provide a steady source of clean water for different needs.

How Does a Seawater RO Desalination System Work?

Let’s break down the process into simple steps:

Step 1: Water Intake

Water is collected from a source. In coastal countries, this is the sea. In Uganda’s context, water can be taken from saltwater lakes, underground salty water, or by bringing seawater near borders. This water is the feed water.

Step 2: Pre-Treatment

Before the water goes into the RO system, larger particles like sand, dust, or dirt must be removed. This is done through filters. Without this step, the RO membranes can get clogged or damaged.

Step 3: High-Pressure Pump

The water is pushed with very high pressure into the RO membranes. This pressure forces water through the tiny pores of the membrane.

Step 4: RO Membrane

The membrane allows only water molecules to pass through. Salt and many impurities are left behind. This is the main desalination process.

Step 5: Fresh Water Output

The water that passes through the membranes is fresh water. This is called permeate. It is collected and sent for storage or direct use.

Step 6: Brine Disposal

The remaining salty water, which contains the concentrated salts, is called brine. This brine must be safely disposed of or treated further.

This whole system must be maintained carefully to ensure long life and reliable operation.

Parts of a Typical Industrial RO Plant

Here are the main pieces of a desalination system:

-

Water intake pumps

-

Pre-filters

-

High-pressure pumps

-

RO membranes

-

Control system

-

Energy recovery devices

-

Storage tanks

Some modern plants even use energy recovery systems to save power and lower costs.

Challenges Uganda Faces With Seawater RO Desalination

While the technology has many benefits, there are also challenges, especially in a landlocked and developing country like Uganda:

1. High Cost

Building an industrial seawater RO plant is expensive. It requires major investment in machines, infrastructure, and trained staff.

2. Energy Requirements

RO systems need a lot of energy. Electricity must be reliable, otherwise, the plant will not work well. This can be a challenge where power supply is not always stable.

3. Transportation of Seawater

Since Uganda does not border the sea, bringing seawater to the plant is difficult unless the plant is built near saltwater lakes or imported water is used.

4. Brine Disposal

After water is purified, the leftover salty water (brine) must be disposed of safely. If this brine is released into lakes or rivers without treatment, it may harm the environment.

5. Skilled Staff

Operators need training to manage the systems. Skilled engineers and technicians are required for daily operation and maintenance.

Despite these issues, if supported by good planning and investment, RO desalination systems can still become part of Uganda’s future water solutions.

Possible Solutions to These Challenges

Uganda can take several steps to make desalination systems more successful:

1. Use Renewable Energy

Solar power is strong in Uganda. Solar panels can power RO plants, reducing energy costs and reliance on unstable electricity.

2. Public and Private Partnerships

Government and private investors can work together to share costs and expertise. This can make big projects more affordable.

3. Small and Portable Plants

Smaller or modular desalination units can be used in rural areas or places with urgent water needs. These systems are easier to install and require less infrastructure.

4. Training Programs

Investing in training for technicians and engineers will build local skills. Trained staff can handle daily operations and fixes.

5. Safe Brine Management

Finding ways to treat or reuse brine, such as in salt production, can reduce environmental harm.

Benefits of Industrial Seawater RO Desalination for Uganda

Here are the main benefits if Uganda adopts seawater RO desalination:

Clean Drinking Water

People can have reliable access to safe drinking water even in dry seasons or drought conditions.

Support for Industries

Industries can grow because they will have the water they need. This can help create jobs and boost the economy.

Better Farming

With more clean water, irrigation can improve. Farmers can grow more crops and produce better yields.

Health Improvements

Clean water means fewer waterborne diseases. This improves health for families and communities.

Reduced Pressure on Rivers and Lakes

When desalination supplements water supply, natural sources like lakes and rivers do not get overused as much.

The Future of Desalination in Uganda

Right now, Uganda has very little to no large-scale seawater desalination plants. Studies show that water-scarce developing countries like Uganda still have low adoption of desalination technologies.

But as population and climate pressures rise, the role of desalination may grow. More affordable, energy-efficient systems are being developed across the world. If Uganda plans well, it can use these technologies in future decades.

With government support, international funding, private investment, and new innovations, seawater RO desalination could become a key part of the water solution in Uganda.

Conclusion

Industrial seawater RO desalination systems are a powerful technology that turn salty water into clean, usable freshwater. Even though Uganda is landlocked and faces many challenges, such systems still hold promise, especially when combined with renewable energy and smart planning.

Water scarcity is a real challenge in many parts of the country. Industrial desalination can be part of a long-term water strategy. It can help families get clean water, support factories, and boost economic growth.

For more insightful articles related to this topic, feel free to visit social.mparaki.gr