A High Precision Thin-Wall Mold For Food Packaging is an advanced tooling system engineered to produce disposable food containers with wall thicknesses below 0.5mm while maintaining dimensional tolerances within microns. The design philosophy prioritizes absolute geometric fidelity across millions of production cycles, requiring tool steel selection of exceptional hardness and wear resistance. Cavity surfaces are machined to optical-grade finishes through multi-axis CNC milling followed by manual polishing or electrical discharge machining processes. The dimensional precision of a High Precision Thin-Wall Mold For Food Packaging directly determines container stackability, sealing compatibility with lidding films, and reliable denesting performance in automated filling lines. Engineers specify tolerance bands as tight as ±0.02mm for critical features including rim flatness, corner radii, and stacking lugs.

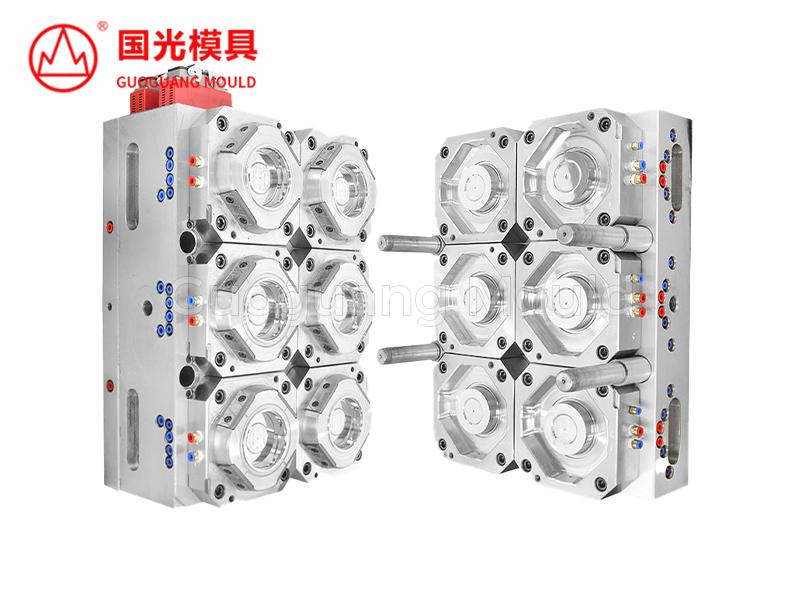

The cavity and core inserts of a High Precision Thin-Wall Mold For Food Packaging are manufactured from vacuum-hardened tool steels such as H13, Stavax, or stainless grades with chromium content exceeding 13%. These materials provide necessary corrosion resistance against off-gases produced during high-temperature polymer processing. Texturing of cavity surfaces through chemical etching or laser ablation creates controlled surface roughness that facilitates air evacuation during filling and controlled release during ejection. The precision interface between moving mold components—including slide actions for undercut features and collapsible cores for threaded closures—requires guide clearance maintained within 0.005mm to prevent flash formation or galling. Each critical dimension is verified through coordinate measuring machines with volumetric accuracy below 2 microns.

The thermal management system within a High Precision Thin-Wall Mold For Food Packaging is engineered to maintain isothermal cavity surface conditions throughout the molding cycle. Conformal cooling channels, fabricated through direct metal laser sintering or five-axis drilling, follow the three-dimensional contour of the container geometry. Computational fluid dynamics analysis optimizes coolant flow patterns to achieve temperature uniformity across the cavity face within ±1.5°C. This thermal precision eliminates differential shrinkage that would otherwise distort container geometry. The integration of high-resolution thermocouples at multiple cavity locations provides real-time feedback for closed-loop process control. The uncompromising approach to dimensional accuracy and thermal uniformity distinguishes High Precision Thin-Wall Mold For Food Packaging as the enabling technology for lightweight, material-efficient food packaging that meets rigorous automation and consumer expectations.