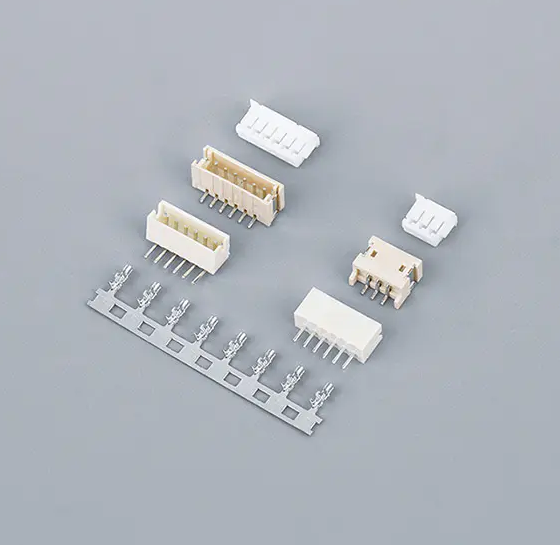

The quality of electronic connectors depends heavily on materials and manufacturing standards. P.C. Board-In Connectors rely on precise metal contacts for conductivity and robust insulating housing to prevent short circuits. Using high-quality materials ensures long-term performance and resistance to environmental factors.

A reliable Terminal Strip Connector Factory implements strict quality management practices. Each connector batch undergoes testing for mechanical strength, electrical resistance, and durability. This approach reduces defects and improves the overall reliability of electronic systems. Terminal strip connectors also require careful material selection to handle multiple wiring connections without degradation.

Design engineers must consider contact plating, plastic composition, and thermal performance when selecting connectors. P.C. Board-In Connectors with corrosion-resistant contacts maintain conductivity over time, while insulating plastics prevent electrical failures under heat or moisture exposure. Collaboration with a Terminal Strip Connector Factory ensures that these requirements are met consistently.

The use of standardized quality practices in connector manufacturing improves device performance, simplifies maintenance, and reduces operational risks. By focusing on materials and quality control, companies can develop systems that function reliably in diverse applications, from consumer electronics to industrial machinery.

In summary, understanding material properties and quality management in connector production is essential. Incorporating well-designed P.C. Board-In Connectors from a trusted Terminal Strip Connector Factory contributes significantly to the dependability and longevity of electronic devices.