When dealing with electrical wiring, the installation of a Junction Box or a Circuit Breaker Block Junction Box must adhere to a number of safety and code requirements. Both the enclosure that simply houses splices and one that incorporates circuit breakers must meet standards for materials, accessibility, environment, and wiring capacity.

One of the first considerations is the material and sizing of the junction box. According to wiring standards, the enclosure must provide enough volume to accommodate the wires, splices, devices and bonding. If the conductor count or size exceeds the box capacity, overheating or damage may occur. Also, enclosures must not be installed in such a way that they become hidden or inaccessible—for instance, you cannot bury them behind drywall with no access panel. Failure to maintain access means future servicing or inspections may be compromised.

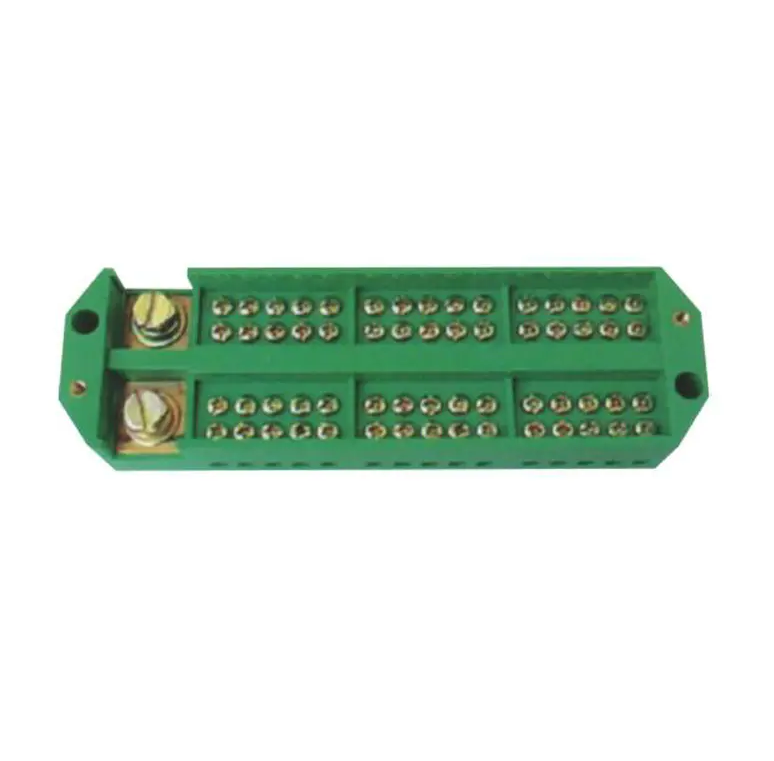

With a circuit breaker block junction box, you have the added layer of protective devices (breakers) inside the enclosure. That means you also need to consider breaker ratings, the enclosure’s rating (for example indoor vs outdoor, dry vs damp locations), and the feeder and branch circuit wiring. The install must ensure that the breaker block is mounted securely, wiring is labeled, and heat dissipation is considered within the enclosure. If multiple high-current breakers are in close proximity inside a small enclosure, heat build-up can degrade insulation or trigger nuisance trips.

Another compliance angle is grounding and bonding. For metal enclosures, the grounding conductor must be connected to the box, and all equipment grounding conductors inside must be spliced or connected appropriately. For plastic enclosures, though the box itself may not require bonding, the internal splices and terminations still require proper grounding paths, and you must ensure that any conduit, cable clamps or terminations protect the wiring and maintain mechanical stability.

In addition, environmental conditions matter: Outside panels or enclosures near wash-down areas must have appropriate ingress protection, gaskets, corrosion resistance and suitable conduit entries. If a circuit breaker block junction box is installed outdoors or in a harsh environment, you need to account for sealing, UV exposure, temperature variation and possible condensation. Failure to do so may lead to failures or accelerated wear.

Finally, from a documentation and inspection standpoint, you should have clear labeling of each circuit within the breaker block, documentation of feeder size and breaker ratings, and service logs for maintenance. Labeling not only helps during servicing but also helps during inspections and audits.

In summary, whether you are installing a simple junction box to join wiring or an advanced circuit breaker block junction box to localize distribution and protection, attention to code compliance, materials, accessibility, heat management, grounding and environmental protection is essential. With these considerations addressed, the installation will align with safety expectations, support future servicing, and operate reliably.