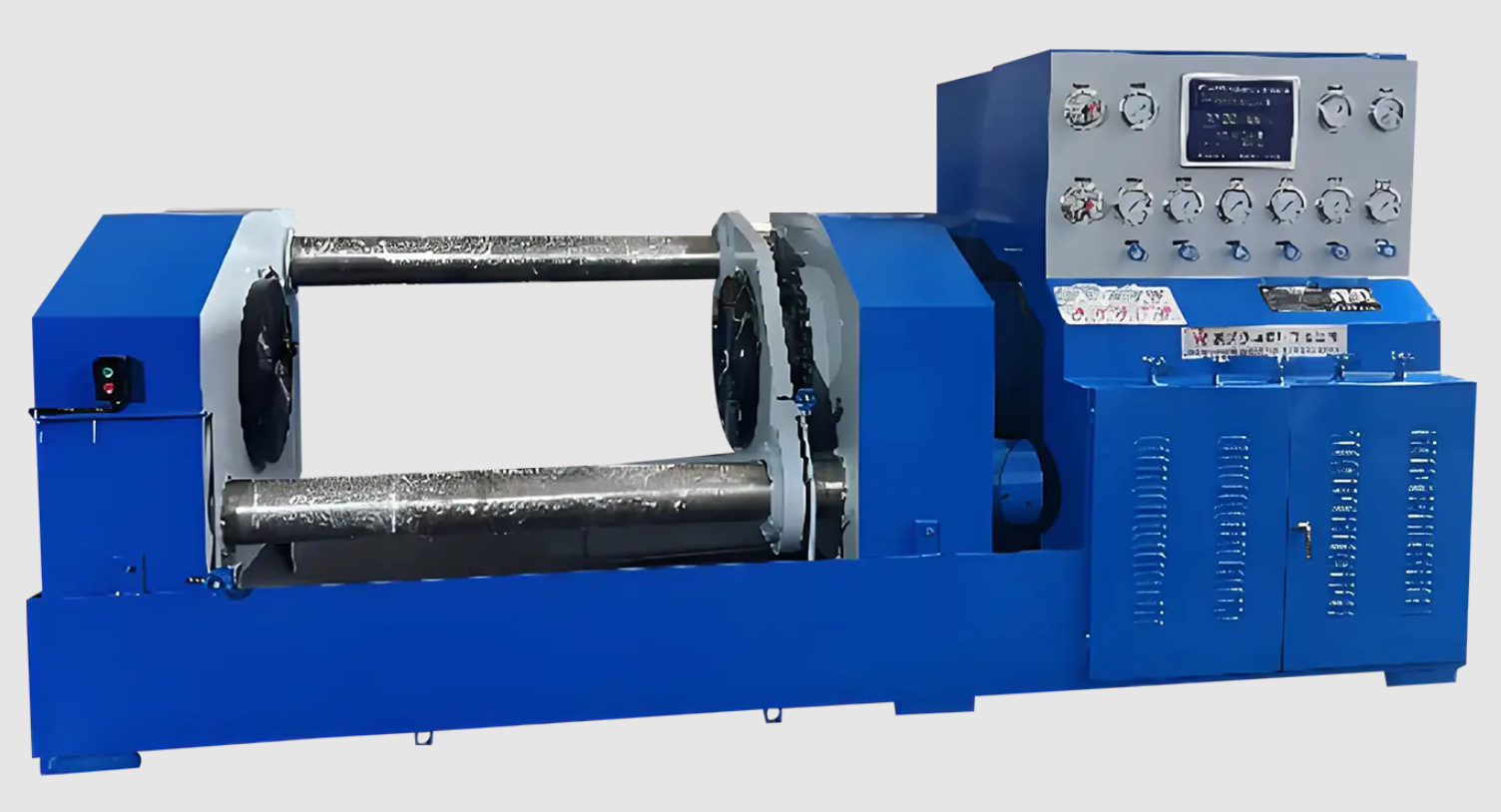

Valve Test Bench Machine, Ball Valve Test Bench are essential equipment for evaluating the operational integrity of industrial valves under controlled conditions. Zhejiang Duojia Hydraulic Co., Ltd. produces a range of these machines, designed to accommodate various valve sizes and types while providing consistent performance measurement. The design focuses on structural stability, precise control, and operator convenience, allowing testing tasks to be conducted efficiently and safely.

The operation of a valve test bench machine begins with secure mounting of the valve. Proper alignment ensures that actuation mechanisms engage smoothly and that measurement sensors capture accurate data. Adjustable fixtures allow operators to accommodate different valve dimensions without significant setup modifications. This flexibility is important for ball valves, as even small misalignments can affect rotation and sealing measurements.

Ball valve test benches utilize hydraulic or pneumatic actuators to simulate operational forces. Sensors monitor pressure, flow rate, and potential leakage points throughout the test. Data acquisition systems record these parameters for analysis, helping engineers evaluate valve performance under expected operating conditions. This approach provides reproducible results without relying on trial-and-error methods.

Regular maintenance enhances machine longevity and accuracy. Hydraulic components, such as pumps, cylinders, and valves, require periodic inspection to prevent wear or fluid leakage. Sensors and control interfaces are calibrated routinely to maintain precise readings. Zhejiang Duojia Hydraulic Co., Ltd. designs their equipment with easy access to critical parts, simplifying maintenance and reducing downtime.

Monitoring techniques include continuous observation of valve behavior during actuation cycles. By tracking rotational movement, pressure response, and leakage, operators can determine whether a valve meets specification requirements. Ball valve test benches can simulate multiple operational scenarios, including repeated cycles and pressure variation, to assess performance over time.

Operator ergonomics and safety are integrated into the design. Work surfaces are positioned to minimize strain, and adjustable fixtures reduce manual effort during valve installation. Safety features such as emergency stops, protective shields, and pressure relief valves ensure that testing can be conducted securely.

These machines are applied across production facilities, maintenance workshops, and research environments. Engineers and quality control personnel use valve test bench machines to validate new designs, troubleshoot existing products, and ensure compliance with operational standards. The ability to document test results digitally supports quality assurance processes and regulatory compliance.

Zhejiang Duojia Hydraulic Co., Ltd. emphasizes modularity in their design, allowing test benches to accommodate a range of valve sizes and operational pressures. This adaptability reduces the need for multiple machines while providing consistent and accurate testing capabilities. Proper use of these machines ensures that valves deployed in industrial systems perform reliably and maintain operational safety.