Optical Brightener for Plastic, Fluorescent Whitening Agents are commonly incorporated into polymer materials to enhance visual whiteness and brightness. Their effectiveness relies on chemical stability, uniform dispersion, and compatibility with the plastic matrix. Proper selection and processing ensure that the additives perform consistently without compromising mechanical or thermal properties of the material.

Efficiency of optical brighteners depends on factors such as polymer type, processing temperature, and additive concentration. Thermoplastics like polypropylene, polyethylene, and polystyrene are widely used with fluorescent whitening agents, while thermosets may require specialized brighteners to withstand curing temperatures. The emission wavelength and absorption profile must align with the base polymer to achieve the desired optical effect.

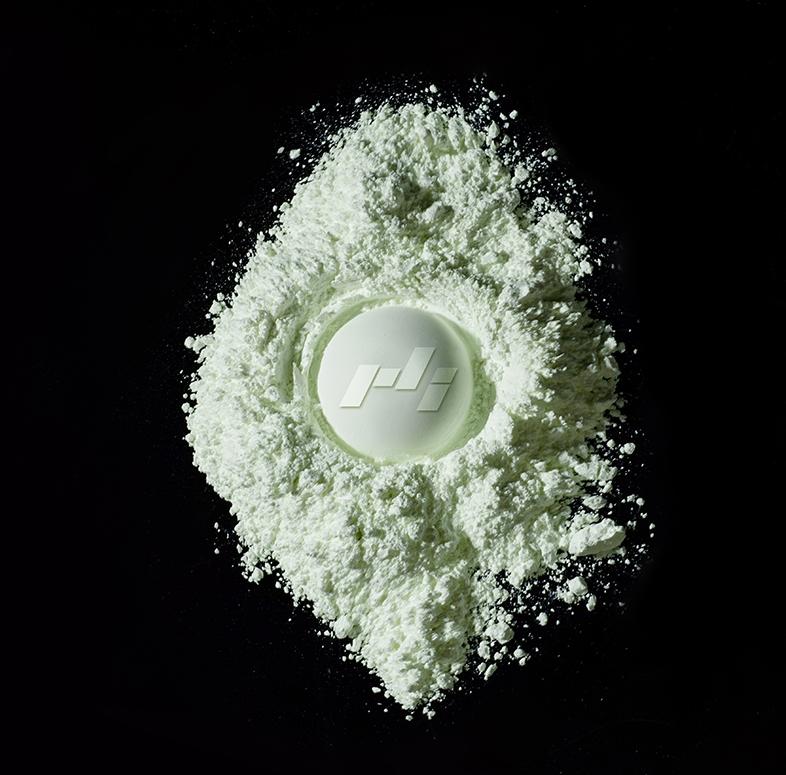

Mixing techniques influence dispersion and uniformity. Dry blending, masterbatch incorporation, and pre-dispersed pellets are standard approaches. Dry blending involves careful weighing and mixing of the powdered additive with resin granules. Masterbatch methods allow higher additive concentrations in a carrier resin that is later blended with the main polymer. Pre-dispersed pellets reduce handling challenges and improve homogeneity during high-speed extrusion or molding operations.

Challenges in plastic brightening applications include additive degradation, uneven distribution, and interactions with pigments or stabilizers. High processing temperatures or extended residence times can reduce brightener efficiency. Uneven dispersion may result in streaks, spots, or inconsistent brightness. Compatibility testing is essential to prevent color shifts or reduced performance when multiple additives are present.

Applications of optical brighteners extend to packaging materials, household products, automotive components, and transparent or semi-transparent items. In packaging, improved whiteness enhances visual appeal and consumer perception. Household plastics benefit from a cleaner appearance, while automotive and electronic components maintain consistent aesthetics over time. Fluorescent whitening agents also compensate for minor yellowing during storage or exposure to UV light.

Optimizing additive concentration and processing parameters requires careful monitoring. Laboratory tests often evaluate brightness, whiteness index, and dispersion uniformity. Adjustments in melt temperature, screw speed, or mixing time help achieve consistent results. These practices support predictable optical performance across production batches.