Special Medical Needles and Industrial Needles share the common requirement of high precision, though their operational contexts differ. Medical needles demand sterility and patient safety, while industrial needles focus on strength and longevity. The production of both types involves quality control, material research, and process optimization, reflecting the broader complexity of modern manufacturing.

Quality Control Measures for Needle Production

Every needle, regardless of its category, undergoes rigorous inspection. In medical needle production, dimensional checks, tip sharpness tests, and surface smoothness assessments are standard. Automated vision systems detect microscopic defects, and samples are tested for strength, flexibility, and uniformity. Sterilization methods such as gamma radiation or autoclaving are carefully validated to maintain safety.

Industrial needles face different quality parameters. Hardness, wear resistance, and resistance to bending are evaluated to ensure reliable performance in high-speed or repetitive processes. Coatings are checked for adhesion and uniformity, and batch testing ensures consistent dimensions. Both types of needles rely on traceability systems, allowing manufacturers to identify production issues and maintain accountability.

Environmental Considerations in Needle Manufacturing

Needle production involves metalworking, coating, and sterilization, each with environmental implications. Waste management, recycling of metal scraps, and control of chemical residues are essential for reducing environmental impact. Advanced filtration and solvent recovery systems minimize airborne contaminants, while water recycling in polishing and cleaning operations conserves resources.

Medical needle production also emphasizes safe disposal of defective units, often through autoclaving and controlled incineration. Industrial needle manufacturers may repurpose or recycle worn needles to reduce material waste. Sustainability practices increasingly influence material choice, coating selection, and energy usage in both sectors, reflecting broader manufacturing responsibilities.

Trends Influencing Future Needle Development

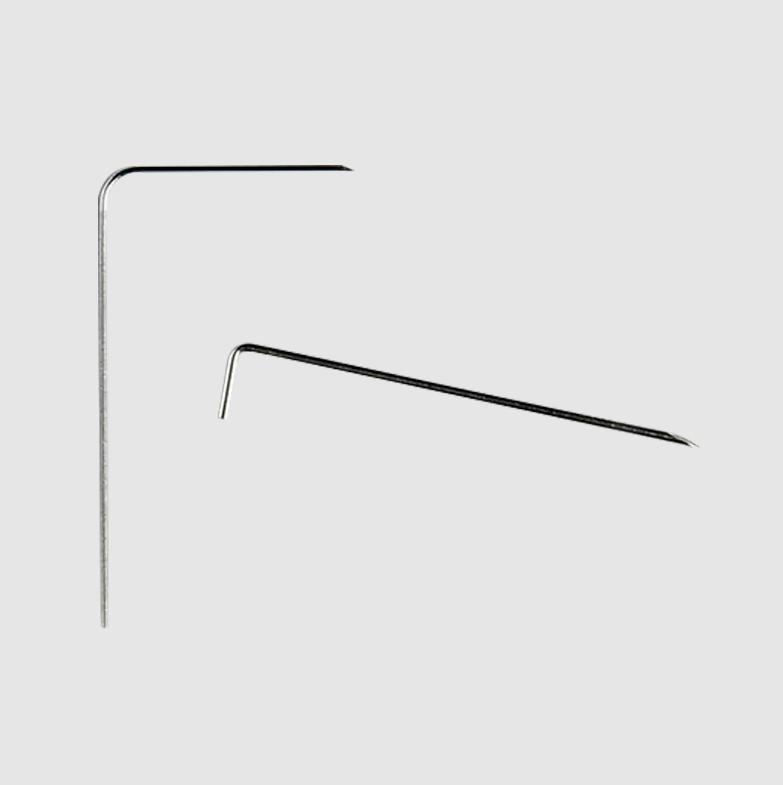

Future developments emphasize precision, durability, and environmental responsibility. Additive manufacturing, laser cutting, and robotic assembly improve consistency and flexibility in needle design. For medical needles, thinner designs and flexible tips support minimally invasive procedures, while industrial needles continue evolving for specialized applications such as high-speed textile or electronics production.

Research in material science drives both sectors forward. Advanced alloys, surface treatments, and hybrid materials offer improved performance and longer lifespan. Automation and digital monitoring enhance production accuracy and traceability. As manufacturers balance efficiency, sustainability, and safety, the evolution of Special Medical Needles and Industrial Needles illustrates the integration of engineering, materials, and technology in contemporary manufacturing practices.