Beverage and consumable industries rely heavily on machinery such as the Wide-Mouth Bottle Blowing Machine and the Mineral Water Bottle Blowing Machine to produce containers efficiently. The choice between these two machines often hinges on the type of product, bottle size, and desired production speed. Wide-mouth bottles are suited for bulk beverages, juices, or condiments, while mineral water bottles follow a standardized design optimized for drinking convenience and portability.

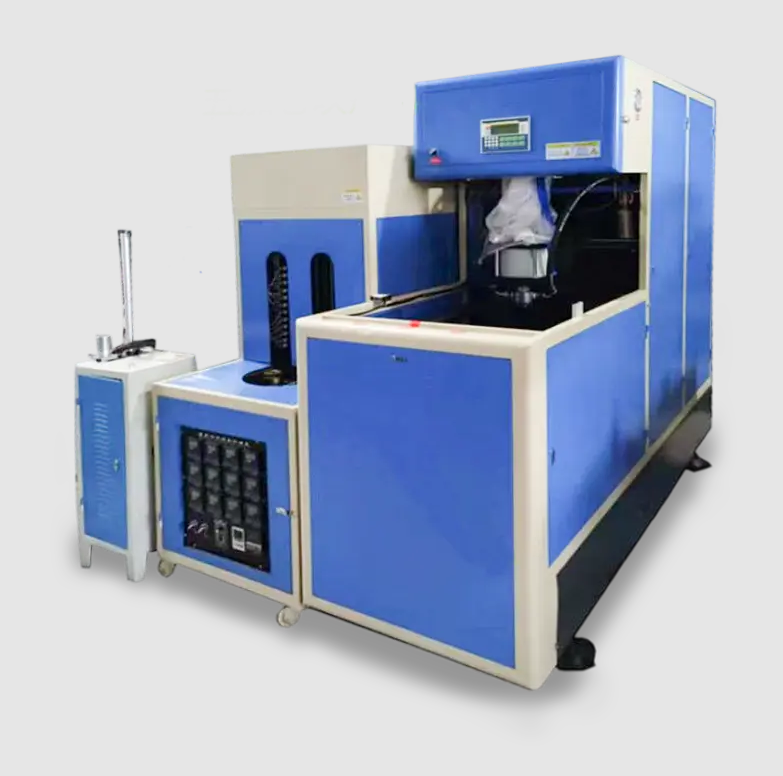

Wide-Mouth Bottle Blowing Machines allow flexibility in bottle capacity and design. Operators can modify molds to adjust bottle height and diameter as required. The process involves heating preforms to achieve uniform pliability, followed by air injection to expand the preform within a mold. Machine controls regulate pressure, temperature, and timing to ensure consistent wall thickness and structural integrity. Some models incorporate features like programmable sequences and automated mold swapping to accommodate diverse production needs.

Mineral Water Bottle Blowing Machines focus on high-speed, uniform production. These machines employ synchronized systems for preform handling, heating, stretching, and blowing. Cooling elements and sensors enhance production stability, allowing continuous operation with minimal interruptions. Automated mechanisms reduce human intervention, lowering the probability of production errors and maintaining consistent bottle quality across large batches.

Material selection and preform quality are critical. PET remains the common choice for both machine types due to its transparency, strength, and recyclability. Irregularities in preforms can result in thin walls, surface defects, or uneven shapes. Hence, manufacturers implement quality control measures during preform inspection to prevent defects from reaching the molding stage.

Maintenance routines differ based on operational focus. Wide-Mouth Bottle Blowing Machines require occasional mold adjustments and inspections, while Mineral Water Bottle Blowing Machines emphasize scheduled maintenance on heating elements, air supply systems, and lubrication to sustain high-speed output. Monitoring these elements ensures long-term reliability and minimizes unexpected downtime.

Energy considerations are also essential. High-speed mineral water bottle machines may consume more electricity per hour due to faster heating cycles, yet the overall output compensates for higher consumption. Wide-mouth machines allow greater flexibility for specialized products, accommodating batch variations without major setup changes.