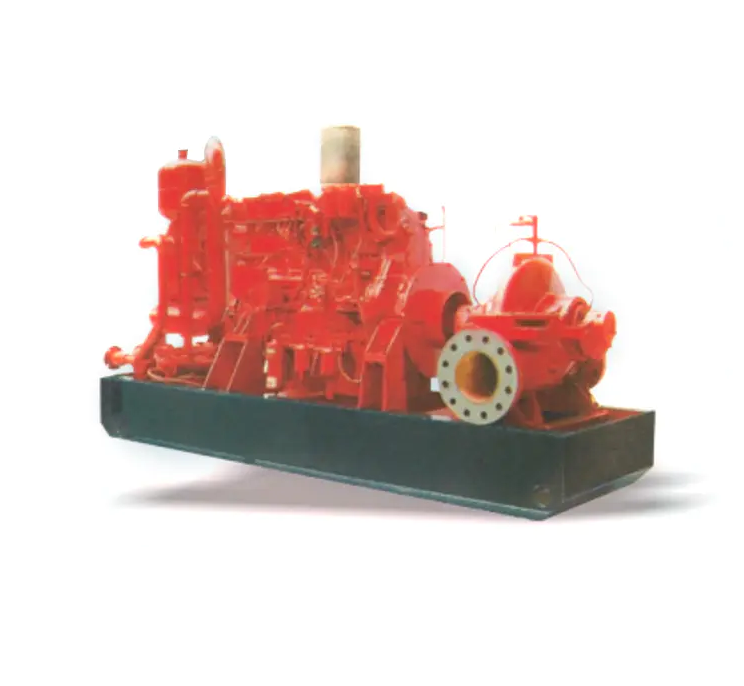

Diesel Engine Pump Factory produces critical components that support engines used in vehicles, machinery, and industrial operations. Pumps must deliver consistent fuel flow, while engines convert energy efficiently to power equipment. High-quality materials and precise assembly processes ensure durability and long-term functionality.

Workflows in Diesel Engine Pump Factory focus on accuracy and consistency. Machining centers, assembly lines, and quality control stations coordinate to maintain steady production. Employees operate specialized equipment to shape, weld, and assemble pump and engine components, keeping tolerances tight and performance predictable.

Material selection drives both performance and lifespan. Metals resist corrosion, wear, and thermal stress, while gaskets and seals maintain tight tolerances under pressure. Lubrication and cooling systems prevent overheating, reducing maintenance frequency. Every component is engineered to meet operational demands across diverse industries.

Testing remains essential. Diesel Engine Pump Factory conducts pressure trials, flow verification, and thermal endurance assessments to ensure pumps function reliably. Engines are evaluated for efficiency and stability under simulated load conditions. This careful examination reduces failure risks in real-world applications.

Energy efficiency impacts both product and production processes. Factory machines operate with monitored energy consumption, while pumps and engines are designed to maximize fuel utilization. Consistent calibration of fuel delivery components enhances engine performance and reduces waste, benefiting both operators and the environment.

Maintenance practices inside Diesel Engine Pump Factory preserve equipment and output quality. Routine inspections, lubrication, and part replacements minimize downtime and support continuous operation. Employees follow safety protocols to reduce risk and maintain a stable production environment.

Research efforts focus on design improvements, fuel delivery accuracy, and enhanced performance. Engineers experiment with materials, pump geometries, and calibration techniques. Prototype evaluation ensures components meet operational expectations and withstand industrial demands.

Supply chain organization keeps production uninterrupted. Raw materials, component inventories, and finished products move efficiently between stages. Careful scheduling ensures engines and pumps reach markets in time, supporting agriculture, transportation, and industrial sectors that rely on reliable diesel machinery.

Environmental and safety considerations shape factory practices. Waste management systems, careful handling of lubricants, and proper ventilation maintain safe, compliant working conditions. Workers benefit from clear procedures, contributing to consistent production and equipment longevity.

Diesel Engine Pump Factory blends engineering skill, material science, and industrial workflow. Its products deliver reliable performance for engines and pumps, supporting industrial operations, transportation, and agricultural needs. Attention to precision, testing, and maintenance ensures components operate efficiently and meet the demanding requirements of modern machinery.