In the rapidly evolving packaging industry, four corner tray boxes have emerged as one of the most versatile, practical, and aesthetically appealing solutions. These boxes are specifically designed to combine strength, stability, and visual appeal, making them suitable for a wide range of industries, including food, cosmetics, electronics, and retail products. This guide provides an in-depth look at four corner tray boxes, covering their design, materials, manufacturing processes, customization options, advantages, and applications.

What Are Four Corner Tray Boxes?

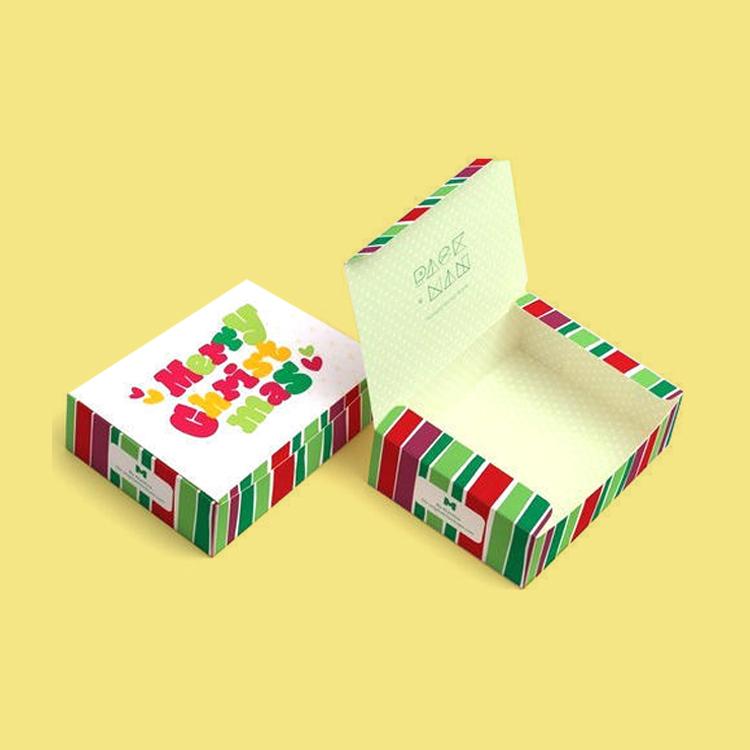

Four corner tray boxes are packaging containers characterized by their rigid structure, formed by folding four corners that create a strong base and open-top tray design. Unlike traditional single-piece cartons, these boxes often come with reinforced corners, providing extra durability and load-bearing capacity. The four corner beers tray box construction ensures that the contents remain secure while offering an elegant presentation, making them ideal for both storage and display purposes.

These boxes are widely used in industries that require a combination of protection and premium presentation, including luxury chocolates, cosmetics, small electronics, and corporate gift packaging.

Materials Used in Four Corner Tray Boxes

The choice of material plays a pivotal role in the strength, appearance, and sustainability of four corner tray boxes. Common materials include:

-

Cardboard: High-quality, rigid cardboard is widely used due to its strength, cost-effectiveness, and recyclability. It is perfect for lightweight products and short-term storage.

-

Corrugated Board: For heavy-duty applications, corrugated board provides exceptional protection against impact, making it ideal for shipping fragile items.

-

Kraft Paper: Known for its eco-friendly properties, Kraft paper offers a rustic and natural look while maintaining durability. It is often used for artisanal or organic products.

-

Plastic: Clear or colored plastic variants allow visibility of the contents and are used in cosmetics, electronics, and bakery packaging.

-

Rigid Paperboard: Premium products often utilize rigid paperboard, which provides a luxurious feel and supports high-end printing and finishes.

Material selection is guided by the product type, target audience, shipping requirements, and branding strategy.

Design Features of Four Corner Tray Boxes

Four corner tray boxes are appreciated not only for their functional benefits but also for their design versatility. Key design features include:

-

Reinforced Corners: Strengthened corners prevent deformation and enhance the box's load-bearing capacity.

-

Open-Top Access: Ideal for easy display, retrieval, and visibility of products.

-

Stackable Structure: Boxes are designed to be stacked securely, saving storage space and ensuring safe transport.

-

Custom Finishes: Options such as matte, gloss, soft-touch, foil stamping, embossing, and spot UV coatings can enhance visual appeal and brand recognition.

-

Die-Cut Windows: Transparent panels or cutouts allow consumers to view the product without opening the box, increasing purchase confidence.

The design process often integrates both aesthetics and practicality, ensuring the box is not just visually appealing but also functional.

Customization Options for Branding and Marketing

Customization is essential in modern packaging as it reinforces brand identity and boosts product appeal. Four corner tray boxes can be customized in various ways:

-

Size and Dimensions: Tailored to fit specific products snugly, minimizing movement and damage.

-

Color Printing: Full-color printing allows logos, product images, and marketing messages to be prominently displayed.

-

Branding Embellishments: Foil stamping, embossing, debossing, and spot UV enhance the luxury perception of the product.

-

Inserts and Compartments: Custom inserts made of cardboard, foam, or plastic ensure product organization and protection.

-

Sustainability Features: Use of biodegradable inks, recyclable materials, and eco-friendly laminates can appeal to environmentally conscious consumers.

A well-designed custom four corner tray box not only protects the product but also acts as a powerful marketing tool that leaves a lasting impression on customers.

Manufacturing Process of Four Corner Tray Boxes

The production of four corner tray boxes involves multiple stages, each critical to ensuring quality and durability:

-

Material Selection: High-quality sheets of cardboard, Kraft paper, or paperboard are chosen.

-

Cutting: The sheets are precision-cut using die-cutting technology to achieve the exact dimensions and fold lines.

-

Folding and Gluing: The four corners are folded and glued to form a robust structure. Automated machines or manual assembly can be used depending on production scale.

-

Printing and Finishing: Digital or offset printing applies branding elements. Special finishes like embossing, foil stamping, or UV coating are added at this stage.

-

Quality Control: Each box is inspected for consistency, strength, and finish to ensure premium quality before packaging the products.

The precision and attention to detail in manufacturing directly impact the functionality, durability, and overall appeal of the final product.

Advantages of Four Corner Tray Boxes

Using four corner tray boxes provides multiple benefits for businesses and consumers:

-

Structural Integrity: Reinforced corners prevent collapsing or damage during transport.

-

Versatility: Suitable for a wide range of products, from fragile items to heavy-duty goods.

-

Enhanced Presentation: Ideal for retail display, allowing products to be showcased elegantly.

-

Eco-Friendly Options: Many materials used are recyclable and sustainable.

-

Cost-Effective Production: Efficient die-cutting and folding methods reduce material wastage.

-

Ease of Use: Open-top design facilitates easy access to contents while maintaining security.

These advantages make four corner tray boxes a preferred choice for premium and everyday products alike.

Applications Across Industries

Four corner tray boxes are adaptable to numerous sectors, including:

-

Food Industry: Used for packaging baked goods, chocolates, snacks, and confectionery, providing both protection and an attractive presentation.

-

Cosmetics and Personal Care: Ideal for soaps, skincare sets, makeup palettes, and perfume sets where luxury packaging enhances consumer perception.

-

Electronics and Gadgets: Provides safe storage for small electronics, cables, and accessories.

-

Retail and E-commerce: Secure packaging solution for shipping, storage, and display of various consumer goods.

-

Corporate Gifting: Premium boxes for corporate gifts, promotional items, and special events enhance brand reputation.

By integrating custom design and branding elements, four corner tray boxes become a versatile solution across multiple industries like Your Box Packaging.

Sustainability Considerations

In today's eco-conscious market, the sustainability of packaging is paramount. Four-corner tray boxes can be manufactured using recycled materials, biodegradable inks, and eco-friendly laminates. Companies increasingly focus on designing boxes that are fully recyclable or compostable, meeting consumer demand for sustainable packaging solutions. By emphasizing environmentally responsible materials, brands can enhance their corporate social responsibility (CSR) profile while reducing their environmental footprint.

Conclusion

Four corner tray boxes offer a perfect combination of strength, functionality, and aesthetic appeal. Their versatility across industries, customization options, and sustainability potential make them a highly effective packaging solution. By investing in high-quality, branded four-corner tray boxes, businesses can ensure their products are protected, presented elegantly, and delivered with maximum consumer impact.