Safety isn't just a feature—it's the foundation of every workplace, especially in risky spots like factories or far-off work sites. At Sigma Power Tech, we craft custom Shelter Control Systems that give people a secure place to stay when danger strikes nearby. As both the manufacturer and service provider of these Shelter Systems, we pour care into every step, ensuring they stand strong and keep everyone inside safe and calm.

Starting with a Deep Look at Your Needs

Our manufacturing journey begins long before tools touch materials. We sit down with you to understand your site's unique challenges—maybe high winds in a desert outpost or chemical risks in a plant. This chat shapes everything, from size to special features, making sure the Shelter Control System fits like a glove.

No two sites are alike, so we sketch plans that match exactly. Our team draws from years of real-world know-how, spotting needs you might overlook. As service providers too, we think ahead to upkeep, building in easy-access spots for future checks. This upfront work prevents headaches later and boosts safety from day one.

Picture a remote gas station crew sharing their daily worries. We listen, then design a shelter that handles heat, dust, and sudden leaks perfectly. Personal touches like this make our systems trusted favorites.

Picking the Strongest Materials for Lasting Strength

Next, we hand-pick materials that laugh off tough conditions. Thick steel frames resist blasts and storms, while special coatings fight rust in wet areas. Walls sandwich insulation for steady inside comfort, no matter the weather outside.

Every choice prioritizes safety—doors that seal tight, windows that stay put under pressure. We test samples in rough setups to prove they hold up. Being the manufacturer means full control over quality, so nothing weak slips through. Our service role reminds us to use parts that stay simple to fix down the road.

In coastal plants where salt air bites, these materials shine, keeping shelters fresh for decades. Clients save big on replacements, turning safety into smart spending.

Crafting Parts with Precision in Our Workshop

Inside our workshop, skilled hands and machines shape each piece. Frames weld strong, doors hang smooth, and air handlers fit just right. We group similar jobs to speed things up without cutting corners, ensuring every Shelter System matches the plan.

Workers check measurements twice, catching tiny slips early. Lights, outlets, and controls wire neatly for foolproof use. As makers, we run daily tests on tools to keep work spot-on. This hands-on care means your shelter arrives ready to protect, not needing fixes right away.

A fun peek: our team often races to assemble a demo unit fastest, sharpening skills for your custom build. Speed meets safety here every time.

Smart Assembly for Seamless Teamwork

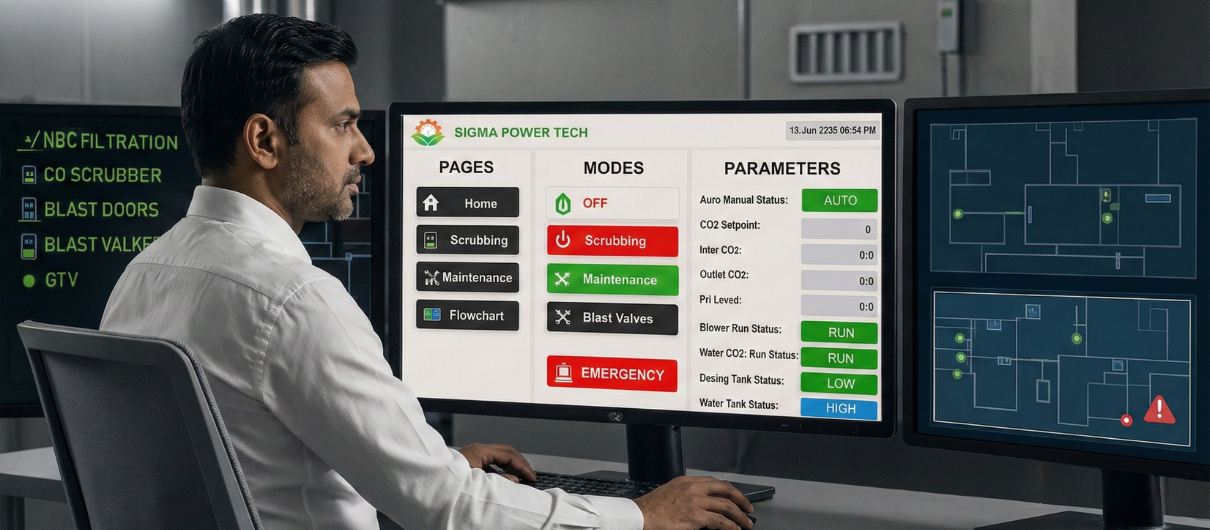

Assembly brings parts alive as one unit. The frame rises first, then walls bolt on firm. Inside, we mount fans, sensors, and the main control box, wiring them to chat smoothly. Every connection tests live—air flows right, lights glow steady, doors lock quick.

We mimic real emergencies during this stage, seeing how the Shelter Control System reacts. Adjustments happen on-site, perfecting before shipping. Our dual role as service provider shines here—we add service hatches and labels for easy future care. No guesswork for your crew later.

Remote sites love this: shelters arrive plug-and-play, cutting setup to hours. One pipeline client marveled at how ours clicked together like building blocks, safe from first use.

Rigorous Testing to Guarantee Top Safety

No shelter leaves without full trials. We pump in fake bad air to check filters, drop pressure to test seals, and cut power to prove backups work. Hours of runs confirm everything holds under stress, from heat waves to power blips.

Teams watch every reading, tweaking as needed for perfection. This proves maximum safety before it reaches you. As manufacturers, we log all data for your records, easing audits. Service plans build on these tests, with follow-up visits to match factory standards.

A standout moment: one unit aced a week-long storm test, emerging flawless. Stories like this build our reputation for unbeatable reliability.

Custom Touches That Fit Your World

What sets us apart? True customization. Need bigger doors for gear? Extra outlets for tools? We add them seamlessly. Colors match your site, signs glow for night shifts. Even app links for phone checks come standard now.

For blast-prone areas, we reinforce frames without bulk. Quiet fans suit noise-sensitive spots. Our manufacturing flexibility lets dreams become durable reality. Service includes training videos tailored to your setup, empowering your team.

Factories request glow-in-dark paths; we deliver. These details turn good shelters into great ones.

Packaging and Delivery with Care

Finished shelters pack smart—padded corners, strapped loads for bumpy roads. We plan routes to dodge delays, often using flatbeds for remote drops. On arrival, our crew unpacks and sets up, testing again to confirm all good.

As service providers, we stick around for handoff training, walking your folks through every button. This full-circle care means zero learning curve.

Shipped to a mountain rig lately, ours climbed rough trails intact, ready same day. Happy crews make our day.

Why Our Full-Service Approach Wins

Pairing manufacturing with service creates unbeatable value. One team knows your shelter inside out—from build to tune-ups. Yearly visits spot wear, upgrades keep it modern. Costs drop with bundled plans, peace rises.

Clients stay loyal because we prevent issues, not just fix them. In 2026's strict safety world, this edge matters.

Ready to Build Your Custom Shelter?

Let's chat about your site today. We'll map risks, craft a plan, and deliver safety fast. As your manufacturer and service provider, Sigma Power Tech turns worries into worry-free operations. Protect your people with a Shelter Control System made just right.