Metalworking is a crucial aspect of modern manufacturing, as it produces items such as blades, automotive parts, and tools. Straight neat oils, synthetic fluids, semi-synthetic fluids, and soluble oils, which are also called emulsifiable oils, are the four primary forms of metalworking fluids.

When making metal items, several steps are involved. Metalworking fluids are often used in milling, turning, grinding, casting, drawing, heading, and stamping, among other things. To achieve optimal performance from modern metalworking fluids, it is essential to monitor them and make adjustments as necessary. However, performing these things without coordination is not the best way to do them.

What Are Metalworking Fluids?

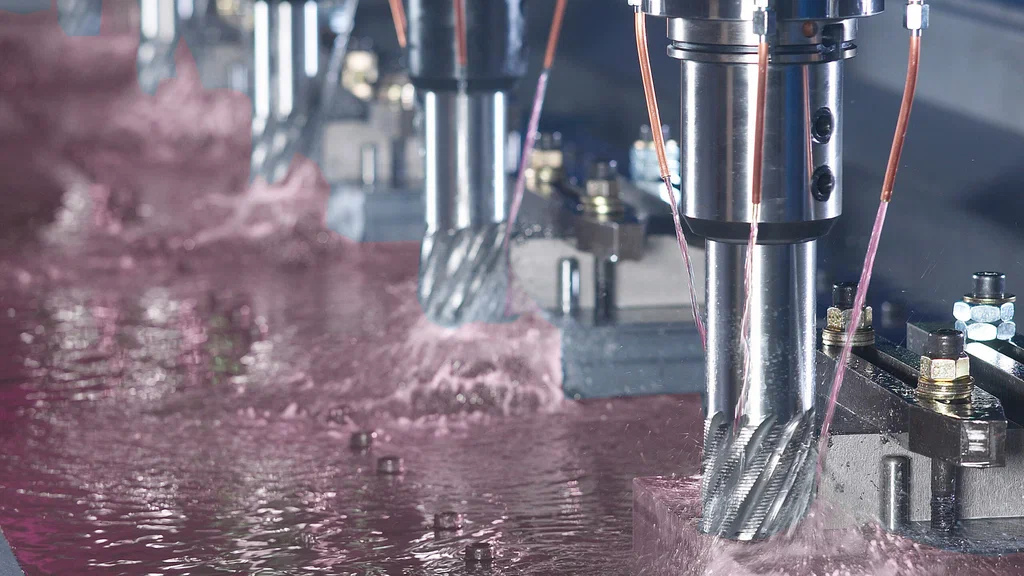

Metalworking fluids (MWFs) are specialized liquids designed to cool, lubricate, and clean metal workpieces during machining. This includes milling, drilling, grinding, and turning. These fluids not only lower heat and friction, but they also help remove metal chips and other debris, which prevents tools from becoming damaged and workpieces from being damaged.

There are several types of metalworking fluids and lubricants, including straight oils, soluble oils, semi-synthetic fluids, and fully synthetic fluids. Each type is designed for a specific purpose, based on the material being cut, the cutting conditions, and the required surface quality.

What Makes the Best Metal Working Fluids?

To select the best metalworking fluids, it is essential to understand the specific requirements of your processes. Some of the most important factors to consider are the ability to cool, the ability to lubricate, the ability to inhibit microbial growth, and the ability to remain chemically stable.

For instance, fluids with minimal foaming properties and good thermal stability are needed for high-speed CNC operations. On the other hand, emulsifiable oils that are very resistant to corrosion might work better for general-purpose lathe work.

The best metalworking fluids for the UAE are those that resist oxidation and remain stable in the sump for an extended period. This is because the temperatures are high, and the machines operate regularly in challenging conditions. This reduces the frequency of fluid changes and lowers the cost of disposal.

Also, new formulas now have lubricants that are chlorine-free, boron-free, and biodegradable. This helps businesses comply with local and international environmental regulations.

Basics and Benefits of Metalworking Fluids

Here are the basics and benefits of different forms of metalworking fluids:

Straight Oils

Mineral, vegetable, or animal oils can all be used to make straight oils. People usually think they are pretty flexible, which makes them suitable for heavy-duty machining tasks. Water does not mix with straight oils; however, severe pressure agents are often added to formulas to enhance their performance.

Synthetic Fluids

Synthetic fluids don't contain any mineral oil; they consist solely of synthetic base stocks. They keep the workpiece wet at all times to prevent mist and haze, especially during grinding. Synthetic fluids are less effective at preventing rust and can be detrimental to tools over time compared to other solutions.

Semi-synthetic Fluids

Mineral oil makes up 5% to 30% of semi-synthetic fluids, while water, which constitutes 30% to 50% of these fluids, dilutes them. Thanks to high levels of chemicals, they can cut through metal and keep everything cool and lubricated.

Emulsifiable or Water-soluble Oils

Oils that can be mixed with water or emulsified typically contain 40% to 70% pure mineral oils and other chemicals that facilitate their combination with water. Soluble oils are used as both coolants and lubricants, especially during cutting and grinding operations. They slow down the welding process between cutting tools and the workpiece, preventing the tools from wearing out.

The sort of problem that metalworking fluids are supposed to solve has a significant effect on which ones you choose. In addition, additives can be added to metalworking formulas to help prevent corrosion, improve performance, reduce mist, emulsify, or enhance the smell.

Because water is good for the growth of microorganisms, any metalworking fluid that has water in it will have some kind of biocide in it. Biocides are typically regarded as additives. Microorganisms can be hazardous to health and safety, causing emulsions to separate, sediments to form, biofilms to develop, and metals to corrode. One motivation for changing the rules around metalworking fluids is to stop undesired microbial activity and the harm it can cause.

Changes in Metalworking Fluid Regulations, Safety, and Efficiency

The industry has made significant strides in ensuring that metalworking fluids are safe for those who work with them. For the past 15 years, the European Union has made it harder to use boron and other biocides that release formaldehyde in industrial settings.

Manufacturers began to work on their goods, which led to more rivalry in the entire market. Newer items, which were safer for consumers to use and worked better than earlier ones, replaced many of them. For instance, Castrol developed its XBB-series without boron or biocides, making it a fully sustainable alternative that requires minimal maintenance and repairs.

Boron and formaldehyde-releasing agents are effective in various industrial and machining formulations, but they can pose health and safety risks to those who use them. The biggest challenge for the entire industry right now is finding solutions that are effective and durable.

Products that effectively dissipate heat and maintain a consistent pH value reduce the need for costly additive top-ups, unnecessary repairs, and hazardous waste associated with changing fluids. The appropriate formulation can lead to higher productivity, efficiency, and competitiveness. This is because a more stable pH value means less microbial activity, resulting in fewer expensive additives needed to combat it. A stable pH also helps fight corrosion and lower maintenance expenses.

Best Practices for Maintenance of Metalworking Fluids

Maintaining your metalworking fluids is crucial if you want them to function effectively and last a long time. Use a refractometer to regularly check the concentration of the fluid and ensure it remains within the recommended range.

It's also essential to monitor tramp oil contamination, check for bacterial growth, and monitor pH levels. Fluid analysis, performed periodically, can help identify early signs of imbalance or degradation. Installing tramp oil skimmers and filtration systems keeps fluids from breaking down and keeps machines safe.

In places like Jebel Ali or KIZAD in the UAE, where heavy-duty machining is standard, companies often use centralized fluid management systems to automate monitoring and filling operations.

Metalworking Fluids and Sustainability in the UAE

Sustainability and manufacturing in the UAE are crucial to the country's industrial strategy. In this situation, there is a growing need for metalworking oils that are safe and environmentally friendly. Manufacturers now seek metalworking fluids that are free of heavy metals, can be recycled, and naturally break down.

Many suppliers, both local and international, are offering modern MWFs that are designed to last longer, generate less waste, and facilitate easier wastewater treatment. This is beneficial for the environment in the UAE and helps businesses reduce their running costs.

UAE manufacturers can meet compliance standards and become more competitive by incorporating sustainability into their choice of fluids and their management.

Wrapping Up

In today's manufacturing, metalworking fluids are more than just lubricants; they are essential tools that significantly impact quality, efficiency, and cost. As the market for metalworking fluids evolves, it becomes increasingly important to understand how these fluids function and how to utilize them effectively.

Choosing the correct metalworking fluids enables operations to run more smoothly, extends tool life, and produces higher-quality products. Selecting the proper metalworking fluids and lubricants can make a significant difference, whether you're machining in Dubai, fabricating in Sharjah, or operating a marine workshop in Fujairah.

Stay ahead of the game by working with suppliers who understand the challenges businesses face in the UAE and can devise innovative solutions to address them.