A PS Skirting is a interior trim profile manufactured from high-impact polystyrene through precision extrusion processes. The production begins with polystyrene resin compounded with impact modifiers to enhance toughness and prevent brittleness during installation and service. Titanium dioxide and other pigments are incorporated to achieve consistent coloration throughout the profile, eliminating the need for surface painting and ensuring colorfastness under UV exposure. Processing aids and lubricants facilitate smooth material flow through extrusion dies while maintaining dimensional stability during cooling. This formulated compound is fed into single or twin-screw extruders operating at controlled temperature profiles, where it is melted, homogenized, and forced through precision-calibrated dies that shape the characteristic skirting profiles. The continuous extrusion method enables PS Skirting production to achieve consistent cross-sectional geometry, smooth surface finish, and precise linear dimensions across high-volume manufacturing runs.

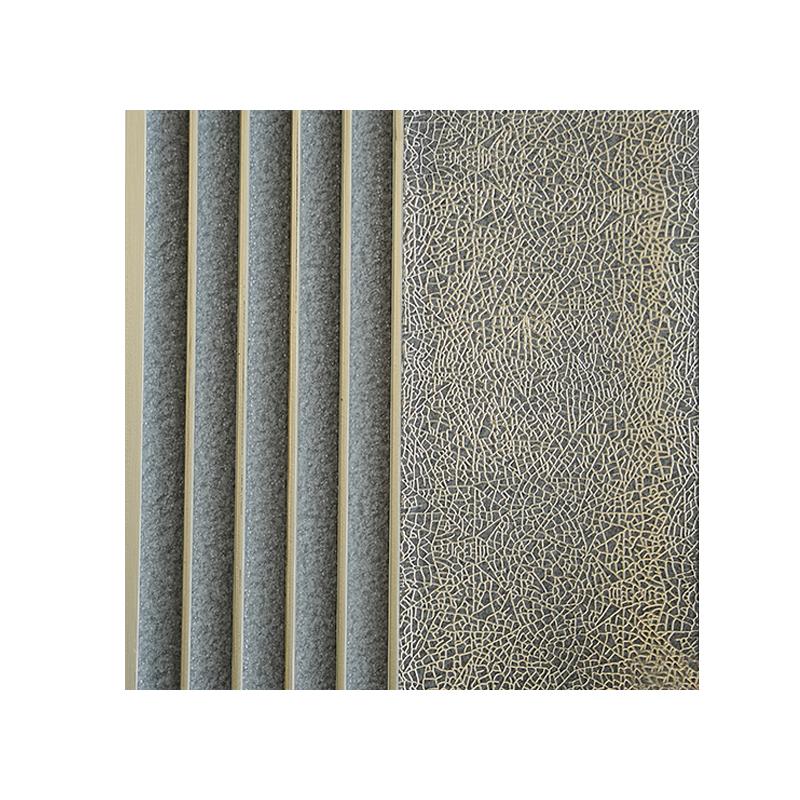

Following extrusion, the continuous profiles enter vacuum calibration tanks where controlled cooling establishes final dimensions and prevents warping or distortion. Automated haul-off units maintain consistent line speed, while flying cutoff saws execute precision length cutting according to production specifications. Surface finishing may include embossing rollers that imprint subtle wood grain or textured patterns, or high-gloss polishing for contemporary aesthetic applications. Quality verification within PS Skirting manufacturing emphasizes dimensional accuracy, impact resistance, and surface integrity. Samples undergo regular testing for flexural strength, impact performance at reduced temperatures, and color consistency measurements. The lightweight nature of polystyrene provides handling advantages during packaging and installation, while the material's inherent moisture resistance eliminates swelling, rotting, or fungal degradation concerns associated with traditional timber skirting.

The manufacturing efficiency of PS Skirting systems contributes to their cost-effectiveness in volume construction applications. The process generates minimal waste, with production scrap and edge trim readily reground and reintroduced into the extrusion feed stream. The combination of continuous extrusion technology, precise calibration systems, and efficient material utilization enables PS Skirting production to deliver consistent quality while maintaining accessibility for large-scale residential and commercial projects.