United States of America– [17-February-2026]

Factory Automation is the application of control systems, robotics, and software technologies to automate industrial manufacturing processes. It minimizes human intervention while improving productivity, precision, consistency, and safety in production environments .By integrating technologies such as programmable logic controllers, supervisory control systems, sensors, and robotic systems, factory automation enables manufacturers to streamline operations, reduce operational costs, and maintain high product quality. It plays a vital role in modern smart manufacturing and Industry 4.0 initiatives, supporting faster production cycles and data-driven decision-making.

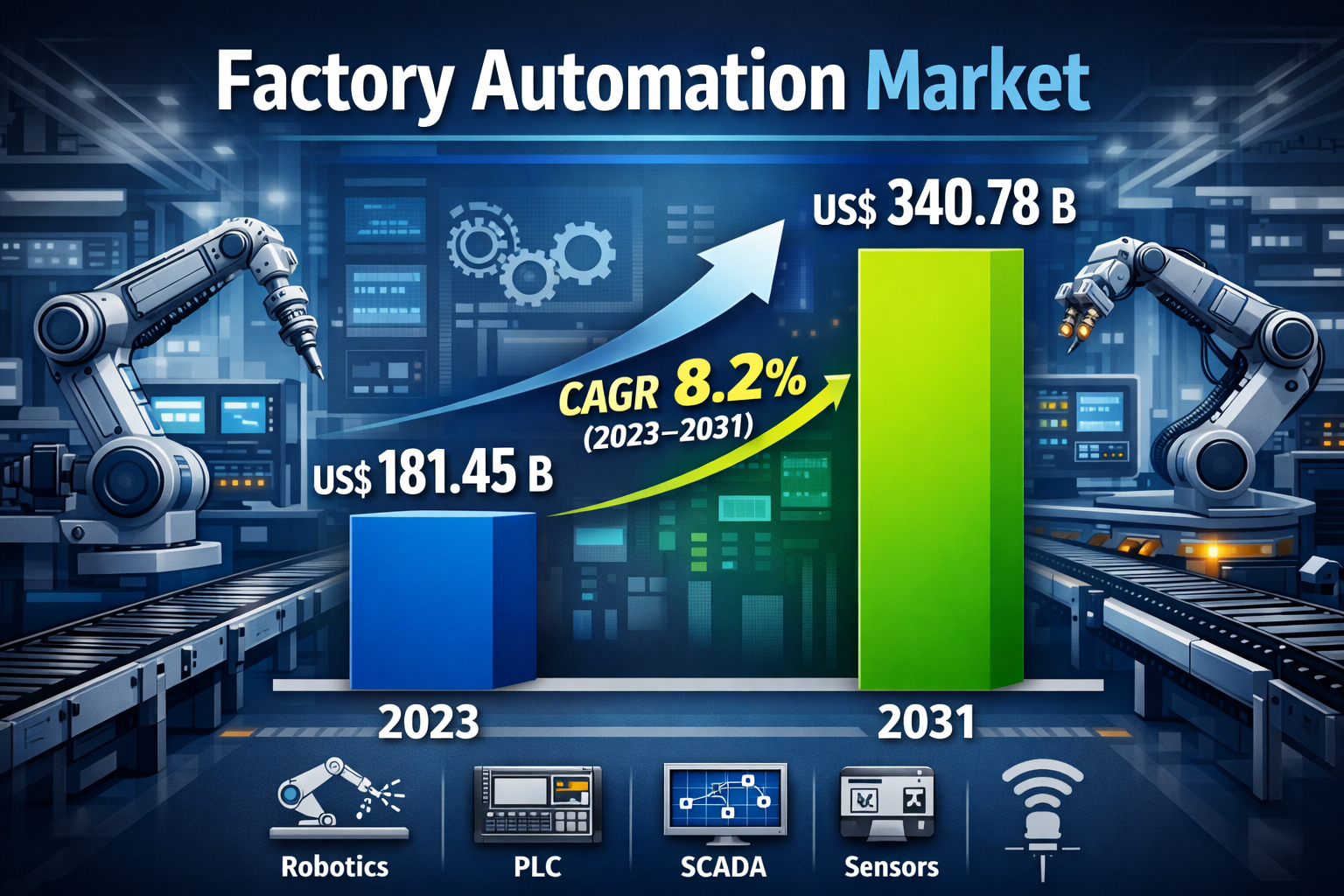

Market Size ,Share And Trends

According To The Insight Partners The factory automation market is anticipated to increase from US$ 181.45 billion in 2023 to US$ 340.78 billion by 2031, registering a compound annual growth rate of 8.2% during the forecast period. The growing integration of machine vision technologies with deep learning capabilities is expected to emerge as a major trend shaping market development .Increasing adoption of machine vision systems combined with deep learning and artificial intelligence is driving advancements in automated production capabilities .Factory automation involves the implementation of automated systems across all stages of manufacturing.

Market Drivers

A key factor driving growth in the factory automation market is the adoption of Industry 4.0 principles. This industrial revolution emphasizes the use of intelligent systems, big data, cloud computing, and advanced IT infrastructure. Manufacturers leveraging Industry 4.0 technologies benefit from improved operational efficiency, faster production cycles, and enhanced agility. The resulting increase in productivity and profitability has encouraged more industries to invest in factory automation solutions.

Another driver is the strategic focus of leading market players on mergers, acquisitions, and collaborations. These activities strengthen product portfolios, expand market reach, and foster technological innovation. For example, major companies have acquired or partnered with cloud-based smart manufacturing and traceability platforms to provide end-to-end automation solutions.

Get a PDF Copy @ https://www.theinsightpartners.com/sample/TIPRE00009863

FAQ

1.What are the main drivers of the factory automation market?

Major drivers include the adoption of Industry 4.0 technologies, rising demand for operational efficiency, increasing labor costs, advancements in AI-powered machine vision, and strategic mergers and collaborations among leading companies.

2.What types of factory automation systems are available?

Factory automation systems are categorized into fixed automation, programmable automation, and flexible automation. Flexible automation is increasingly preferred due to its ability to adapt quickly to changing production requirements.

3.How is the factory automation market segmented?

The market is segmented by component (hardware and software), type (fixed, programmable, flexible automation), technology (PLC, DCS, SCADA, HMI, and others), and industry vertical (automotive, food and beverages, oil and gas, manufacturing, mining, and others).

4.Which industries benefit the most from factory automation?

Industries such as automotive, food and beverages, oil and gas, electronics, and general manufacturing benefit significantly due to high production volumes, quality requirements, and the need for operational efficiency.

Segmentation Analysis

The factory automation market is segmented based on component, type, technology, and industry vertical.

- By Component: Hardware and Software

- By Type: Programmable Automation, Fixed Automation, Flexible Automation

- By Technology: Programmable Logic Controller (PLC), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition Systems (SCADA), Human Machine Interface (HMI), and Others

- By Industry Vertical: Automotive, Food and Beverages, Oil and Gas, Manufacturing, Mining, and Others

Hardware components include robotics, controllers, sensors, and actuators. Software components include manufacturing execution systems, analytics, and control applications. Flexible automation systems allow easy adaptation to changing production requirements, whereas programmable and fixed automation systems provide high precision for repetitive processes.

Regional Insights

Geographically, North America is expected to maintain a dominant share of the market due to early adoption of automation technologies, strong research and development capabilities, and government initiatives supporting digital transformation. Europe is also experiencing growth, particularly in the automotive and food and beverage sectors. Asia Pacific is emerging as a key region, driven by industrial expansion, increasing labor costs, and rising investments in smart manufacturing. South and Central America and the Middle East and Africa are gradually adopting automation solutions as industries seek to improve efficiency and competitiveness.

Key Players

The factory automation market is highly competitive, with several established players contributing to technological innovation and market expansion. Prominent companies include:

- ABB Ltd.

- Emerson Electric Co.

- Fanuc Corporation

- General Electric Company

- Mitsubishi Electric Corporation

- Honeywell International Inc.

- OMRON Corporation

- Rockwell Automation, Inc.

- Siemens AG

These companies focus on product development, partnerships, and expansion of their manufacturing capabilities to meet the increasing demand for automation solutions.

Recent Developments

Recent initiatives include Mitsubishi Electric Corporation investing 3.1 billion yen in India to establish a new factory for inverters and other automation control products. Rockwell Automation, Inc. has partnered with cloud-based traceability platforms to enhance product monitoring from raw material sourcing to point-of-sale, reflecting the growing importance of integrated digital solutions in factory automation.

Future Outlook

The future of the factory automation market appears promising, driven by the continued adoption of Industry 4.0 technologies and increasing demand for intelligent manufacturing solutions. The integration of AI, machine learning, and robotics into production processes is expected to enhance operational efficiency and product quality further. Emerging markets in Asia Pacific and South America offer significant growth potential, while established markets in North America and Europe are likely to focus on upgrading existing automation infrastructure.

About The Insight Partners

The Insight Partners delivers market intelligence and consulting services to help clients make informed decisions. The firm covers industries such as Aerospace and Defense, Automotive and Transportation, Semiconductor and Electronics, Biotechnology, Healthcare IT, Manufacturing, Medical Devices, Technology, Media, and Chemicals and Materials.

Contact Information:

Email: sales@theinsightpartners.com

Website: www.theinsightpartners.com

Phone: +1-646-491-9876

Also Available in :